Rhythmically Reactive. Precisely Timed. Wildly Creative.

MIDILLI Configurator gives you a powerful way to build time-based interactions between your buttons, banks, and MIDI messages — all through its Automation system.

This post is part of a quick, yet comprehensive guide (QCG) series by MIDILLI.

🎛 What Is Automation?

In MIDILLI, Automation means triggering predefined sequences of actions in time — either with millisecond-precision intervals or synced to beats per minute (BPM). It allows you to:

- Send MIDI messages

- Change banks

- Trigger notes, CCs, or SysEx

- … all based on button events and tempo-based timing

🔘 Button-Driven Automation

You define what happens when a button is:

- Pressed

- Released

- Toggled

- Triggered (pulse)

- …or both pressed & released (read more on this).

Each of these can start an automation that:

- Sends MIDI messages at timed intervals

- Changes banks after a delay or on a loop

- Triggers sequences across your devices

And it works across all supported protocols: USB, BLE, or MIDI Out.

🕒 Tempo-Aware MIDI Control

Need to sync actions with a groove? Automation supports:

- BPM-based timing: Define steps in beats

- Tap tempo: Assign one or more buttons to set the tempo

- Auto clock generation: Use automation to send a MIDI clock and drive external devices

Perfect for:

- Creating evolving MIDI patterns

- Switching layers in time with your song

- Building tempo-synced control surfaces for live performance

🔄 Example Use Cases

- Press a button → send a Note On, wait 500ms → change bank, send another message

- Use 2 buttons to tap the tempo → automation sequences adjust timing in real time

- Toggle a button to start/stop a clock-generating sequence, or clips

- Trigger evolving MIDI CCs or SysEx commands at rhythmic intervals

🚀 With Automation, MIDILLI becomes more than a device — it becomes a time-based MIDI engine, reactive to performance and smart in timing.

🎚️ Try it out today and bring motion and structure into your MIDI world.

👉 Read the Full Automation Manual

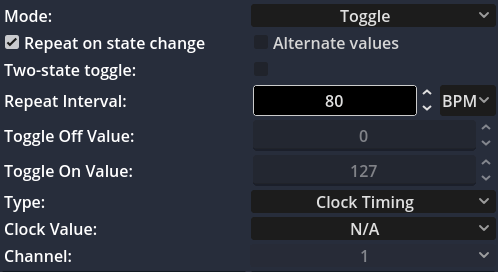

🛠 How to Enable Automation

Getting started with Automation is easy and can be set differently for each bank:

- Select a button inside a bank.

- Define the MIDI action you want (e.g., send CC 90 ranging between 0 and 127).

- Check the “Repeat” checkbox to enable automation. You can make it react on Hold or Toggle On, depending on the button mode.

- Set the Repeat Interval, either in milliseconds or beats per minute (BPM).

- Optionally enable “Alternate values” to send both the minimum and maximum value in succession with a single press.

- Do not forget to switch to the original bank if you are using bank change for automation.

⚠️ Tip: Avoid setting the repeat interval too fast to prevent overwhelming the MIDI buffer.

You can also assign a button to tap tempo, allowing real-time tempo control of automations and MIDI clock sync.

📸 Below is a screenshot showing how to set a tempo after button toggled on at 80 BPM:

Want more tips like this?

📩 Subscribe to our newsletter and get controller design ideas, MIDI tricks, and workflow inspiration straight to your inbox. Read our privacy policy.